OUR PRODUCTS

Perforated Metal Sheet

Perforated Metal Sheet

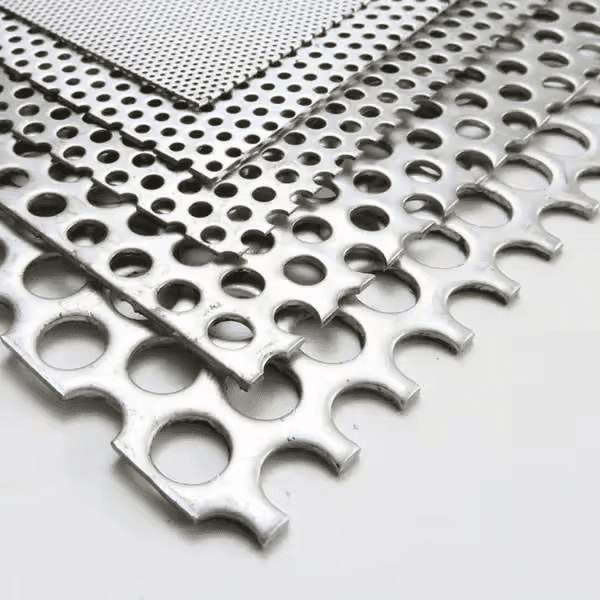

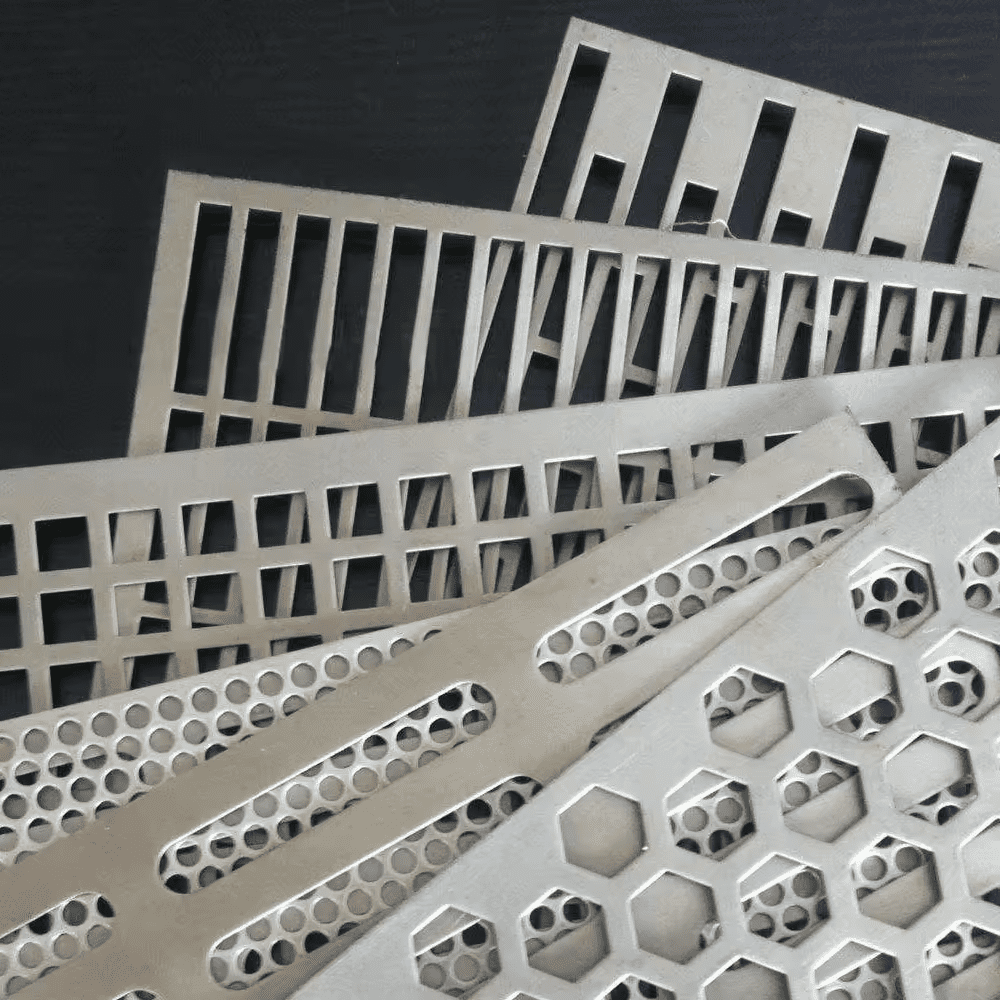

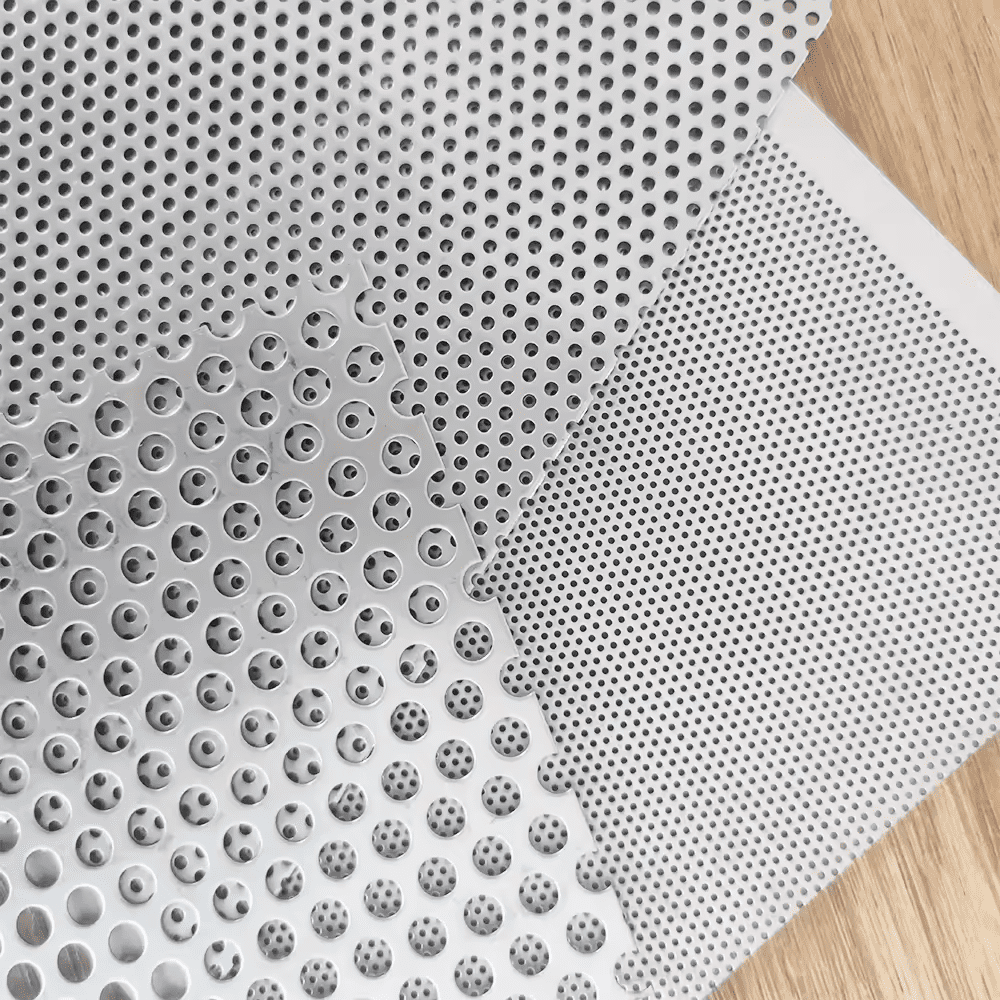

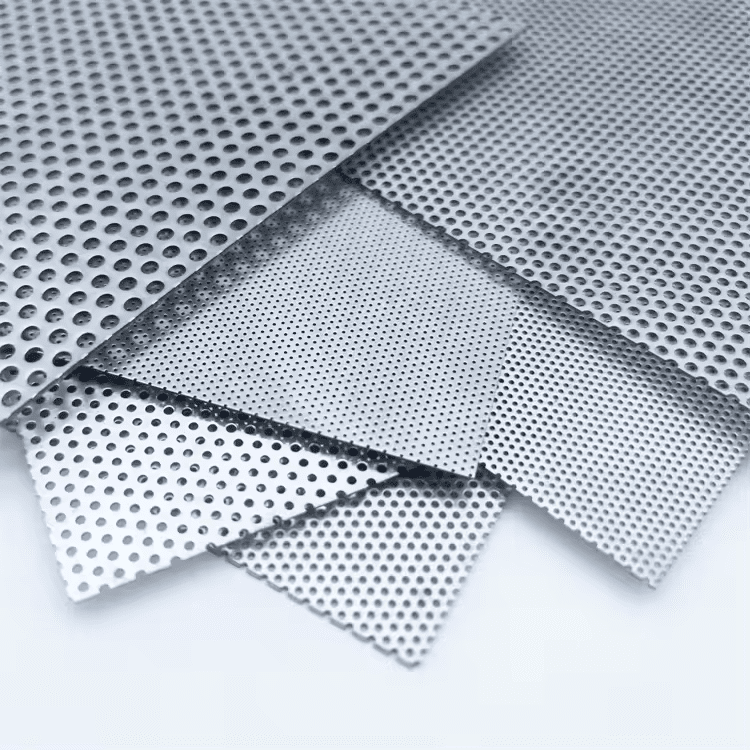

Hole Shapes: Common hole shapes include round, square, rectangular, hexagonal, and custom designs.

Patterns: Holes can be arranged in straight or staggered patterns to achieve different aesthetic and functional properties.

Stainless Steel: Known for its corrosion resistance and strength.

Aluminum: Lightweight and corrosion-resistant, suitable for many applications.

Carbon Steel: Offers high strength and durability.

Copper and Brass: Provide good corrosion resistance and an attractive appearance.

Nickel Alloys: Used for high-performance applications requiring exceptional resistance to heat and corrosion.

Product Introduction

What is perforated metal?

Stainless Steel Perforated Sheets are used extensively in engineering, food processing, building, agricultural and petrochemical industries.

They are used in a number of different applications for a variety of reasons. Used mostly as screens, filters, shields, and guards, Perforated Sheets can control the passage of air, liquid, light, solids, heat, electromagnetic waves, and even sound waves.

With these abilities, Perforated Sheets have applications such as clothes washer and dryer drums, speaker covers, automotive grills and exhaust components, airplane engine silencers, grain dryers, microwave ovens and computer cabinets. Other applications are aesthetics in architectural and design applications such as facades and fixtures.

Perforated metal, also known as perforated sheet or perforated panel, is a sheet metal that has been stamped or punched to create a patterned holes, slots, or decorative shapes. Perforated metal sheets can be made from different materials such as aluminium, stainless steel, mild steel, galvanized steel, brass and more. Perforated metal sheets or perforated panels are lightweight, aesthetically appealing and have great strength, thus they are generally used for cladding purposes and industrial applications. Perforated panels or perforated sheets are versatile, offers good ventilation and have high strength-to-weight ratio which is widely used in filtration applications.

Processing Capabilities

Slitting

Laser Cutting

Punching

Binding Frame

Shaping

Spot Welding

Sintering

End-to-End Welding

Pleating

Injection Molding

Custom Design

Why Choose Us

we can customize wire mesh filters to fit your demands.

Factory Direct

Factory directly which will easy to communicate for us the first, help us of good cost control.

Good Quality

HaoZhou Received ISO 9001 CE Certificate.Quality inspection standard is high.

OEM&ODM Service

The R&D team is experienced to do custom projects and own professional inspection and packing team

Export Experience

With rich experience in product production, the major sales market in north America and Europe.