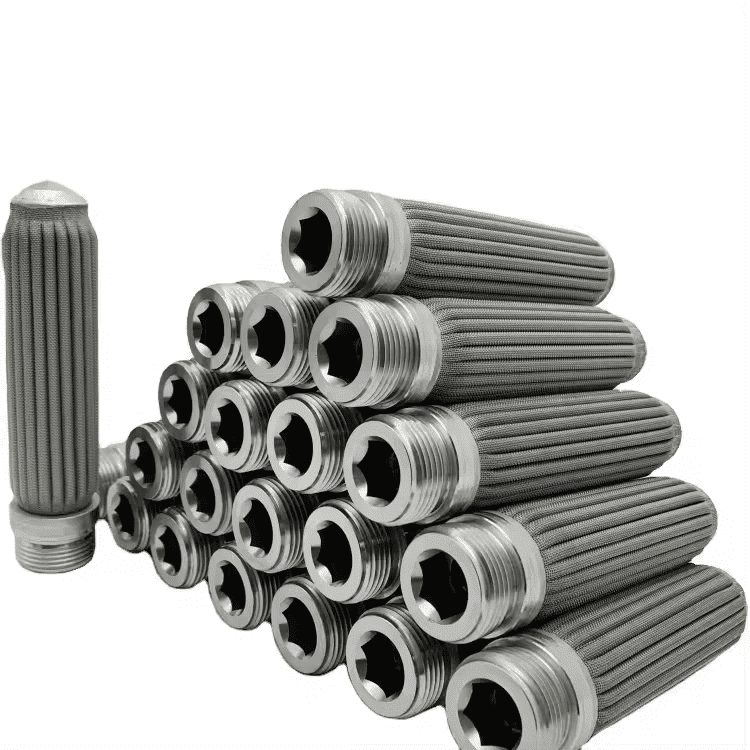

A sintered filter is porous, often, cylindrical metallic part manufactured through the process of sintering. Copper and metal alloys are mixed together and fused through high temperatures achieving porosity and creating a mesh. These filters are used from household appliances to industrial/chemical plants to greater effects and here we will be talking all about the application of sintered filters.

Filtration is an essential aspect of anything we do, from drinking water to gasses used as a coolant in nuclear reactors, impurities cause trouble for everyone. But not everywhere can you use a plastic filter, strainer, chalk, or standard filtration process. Sintered filters perform a very specific task and it is useful in multiple fields of applications, depending upon the microns of porousness.

Advantages of sintered filter:

- Corrosion Resistance

Most of the sintered metals have a natural resistance to corrosive chemicals so they can still maintain a good state under chemical reactions.Sintered glass and sintered ceramic also have excellent performance in corrosion environments.

- Pressure Sustaining

If there are pressure fluctuations during the filtration, the entire system will be affected to some degree.Due to their mechanical strength, sintered metal filters are good at maintaining fluid pressure to ensure stable system operation.

- Robust Durability

Sintered filters have better durability and longer service life in extreme temperatures. With proper maintenance, these sintered parts can be used for many years, often ranging from 3 to 10 years or even longer in some cases, which can reduce the number of replacements, thereby saving costs.

Industry Applications of Porous Filters

- Food and Beverage Industry

For beverage production, you can use filter layers to filter pulp and suspended solids to ensure the clarity of the liquid.

Meanwhile, purified water for food processing can also be obtained by water treatment.

- Chemical Industry

In chemical processing industries, these sintered filters can be used in corrosive environments, like sintered glass filters used in laboratories.

Some chemical waste may be harmful to the environment, which requires some filtration of these substances.

- Electric Industry

You can also use sintered filter elements to remove impurities in the operating conditions. It can maintain the normal operation of the machine and extend the service life.